Wire Cut Edm Machine Working Principle

Wire cut edm wire cutting edm cutting wire burning wire erosion and cheese cutter edm.

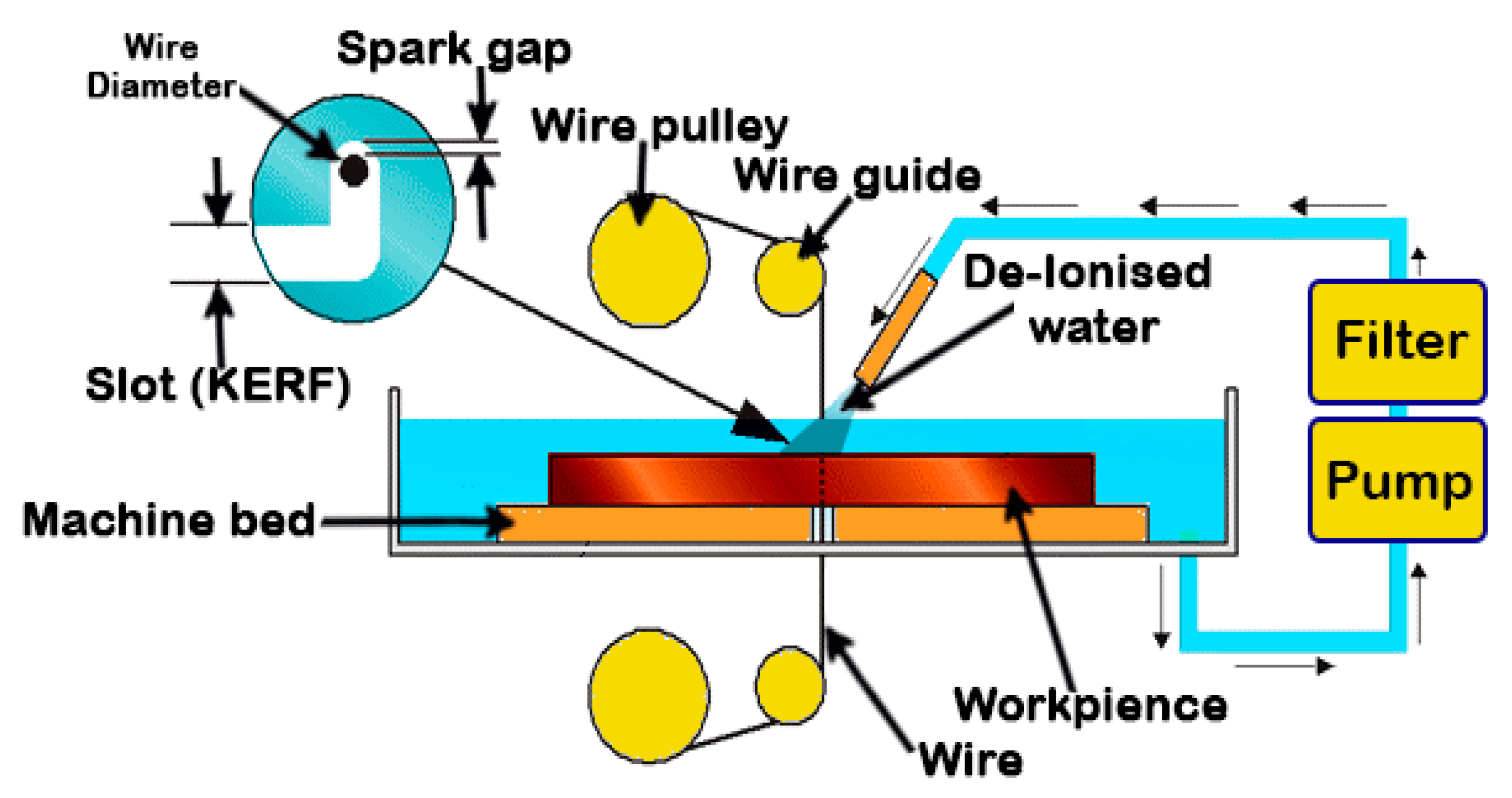

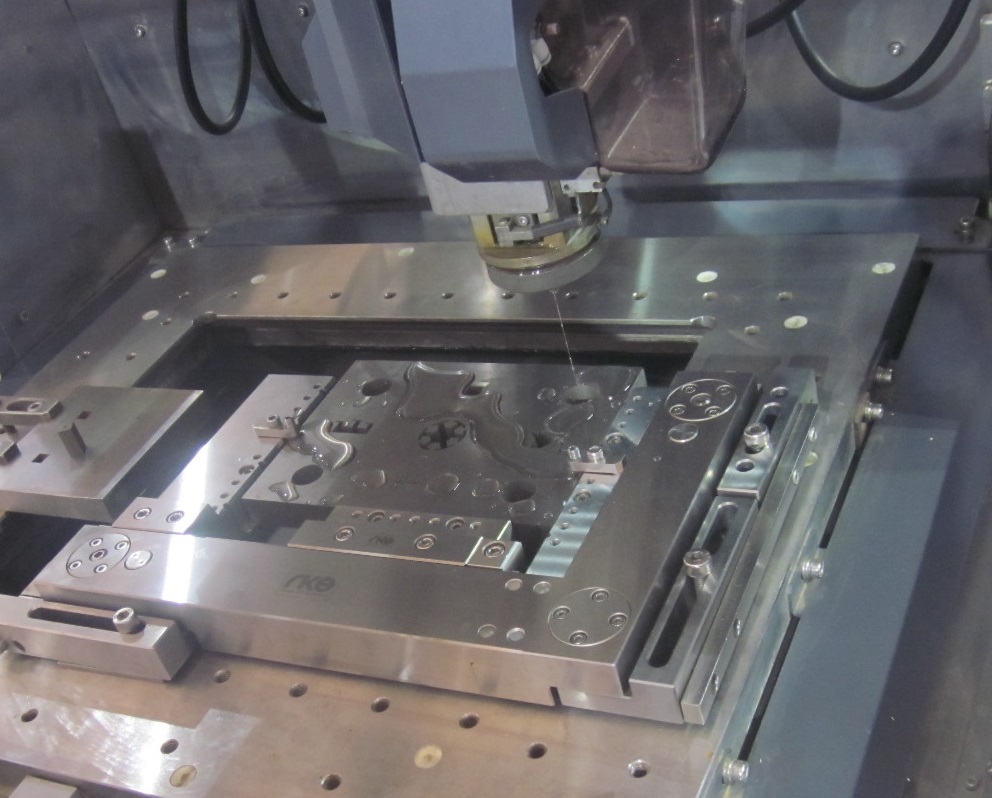

Wire cut edm machine working principle. If the wire breaks while cutting a part the machine senses the break re threads the wire and resumes the cut where the wire broke. In edm machine the material is removed by rapidly recurring repeating discharges of current in between the electrodes. Modern wire edm machines provide automatic threading. Wire edm machining electrical discharge machining is an electro thermal production process where a thin single strand metal wire along with de ionised water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks while preventing rust.

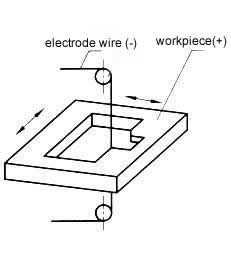

A water jet or air jet guides the wire through the work piece. Wire edm is also known as. Electrical discharge machining edm also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges sparks. Wire electrical discharge machining wedm uses a metallic wire to cut or shape a workpiece often a conductive material with a thin electrode wire that follows a precisely programmed path.

Numerous tiny holes appears due to erosion of impulse discharging and therefore get the needed shape of workpiece as show in figure 1 1. It was first observed in 1770 by joseph priestley. Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes separated by a dielectric liquid and subject. He was an english physicist.